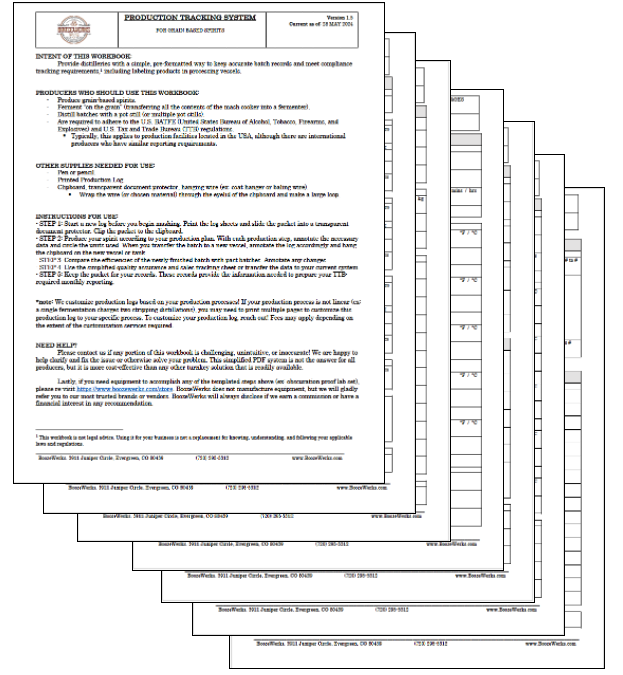

Manual Craft Distillery Production Tracking System- for grain spirits

Manual Craft Distillery Production Tracking System

Efficiency starts with understanding. BoozeWerks has leveraged its decade of spirits production experience into a simplified paper tracking system to record your production processes. All you need is a printer, a few clipboards, and a pen!

Benefits of the Manual Tracking System:

- Keeps you in compliance with TTB regulations by labeling your work-in-progress.

- Captures the data necessary to identify efficiency or quality shortfalls in your production processes.

- Consolidates the required data for your distillery’s monthly TTB reports.

- Keeps your production data organized in a way that is easily integrated into your existing records systems or filed chronologically.

Automated production management software is designed for large companies or complex production processes. These programs are significantly over-featured for many straightforward craft producers and eat $0.20+ per bottle off your bottom line-forever!

Keep it simple, save time, and protect your product, choose the BoozeWerks Manual Craft Distillery Production Tracking System.

Producers Who Should Use This Workbook:

- Producers of grain-based spirits.

- Ferment “on the grain” (transferring all the contents of the mash cooker into a fermenter).

- Distill batches with a pot still (or multiple pot stills).

- Are required to adhere to the U.S. BATFE (United States Bureau of Alcohol, Tobacco, Firearms, and Explosives) and U.S. Tax and Trade Bureau (TTB) regulations.

- Typically, this applies to production facilities located in the USA, although there are international producers who have similar reporting requirements.

STEP 1: Start a new log before you begin mashing. Print the log sheets and slide the packet into a transparent

document protector. Clip the packet to the clipboard.

STEP 2: Produce your spirit according to your production plan. With each production step, annotate the necessary

data and circle the units used. When you transfer the batch to a new vessel, annotate the log accordingly and hang

the clipboard on the new vessel or tank.

STEP 3: Compare the efficiencies of the newly finished batch with past batches. Annotate any changes.

STEP 4: Use the simplified quality assurance and sales tracking sheet or transfer the data to your current system.

STEP 5: Keep the packet for your records. These records provide the information needed to prepare your TTB-required monthly reporting.

BoozeWerks is routinely hired to fix production processes that are no longer performing as originally designed. In our first meeting, these projects start with an unfortunately repetitive conversation:

BoozeWerks, “What were you doing when the process last worked?”

Distiller, “I have the process mostly memorized and adapt on the fly to account for day-to-day changes.”

BoozeWerks, “Do you have any records or data we could review to try and find inconsistencies without wasting time or resources?”

Distiller, “[insert all the reasons the distiller did not, could not, or has not been keeping detailed records].”

BoozeWerks and the Distiller both simultaneously… “uuggggghhhh.”

Please, avoid this all-to-common trap! Our system is reasonably priced, expandable, and customizable (if necessary) to your production process. If you would like to discuss your specific needs or want more information, please contact us!